Tank Inspections

Tank Inspections

Owners and operators of liquid storage tanks are responsible for arranging professional inspection services to be carried out regularly.

All commercial and industrial water and chemical storage tanks must be rigorously examined in accordance with industry standards, ensuring safety and integrity are maintained for their entire lifecycles.

We’ve been a certified tank inspection company for over two decades, supporting local and international businesses and providing tank products, liner, and inspection services worldwide.

In some circumstances, it may be in your best interest as a commercial or industrial site manager to request water testing services in conjunction with an asset inspection – AM Tanks also offers a contents testing component within our inspection services.

AM Tanks’ Inspections - What We Look For

We inspect potable water tanks, chemical tanks, fuel tanks, and bulk dry goods tanks for a range of commonly found complications as storage units age.

State laws require all commercial storage tanks to be annually inspected by a certified professional.

Whether you’re newly installed AM Tanks unit’s ready for its first inspection or you’re concerned about your 20-year-old outdoor concrete setup, we’re equipped to perform a quality inspection and report service on it!

Our standard inspection services include an industry-backed assessment where we’ll look for:

- Hidden cracks in concrete tanks.

- Coating failure.

- Pitting.

- Existing and potential leak points - Deteriorated seams where panels join.

- Surface corrosion - Internal and external wall, floor, and roof surfaces.

- Rusted-out bolts.

- Contamination and MIC - Grime and scale buildup in the tank’s contents.

- Roof damage - Deformations, dents, and possible collapse hazards.

- External wall abrasive damage - Caused by storm debris or operational incidents, etc.

- Damage to directive and safety signage and labeling.

- Accessway and safety component damage - Faulty ladder, railing, fencing, and platform components.

- Potential nesting place for pests and other vermin - Bird-proofing ineffectiveness.

- Issues with the overall structural integrity.

- Drainage-related issues.

- Faulty valves, alarms gauges, nozzles, welds, hoses, and vents.

- Foundational cracking or brittleness.

- Any compromised spill-prevention equipment.

Inspection Types We Offer

AM Tanks provides tank owners, operators, and managers with two types of industrial tank inspection packages, these being:

ROV Tank Inspections

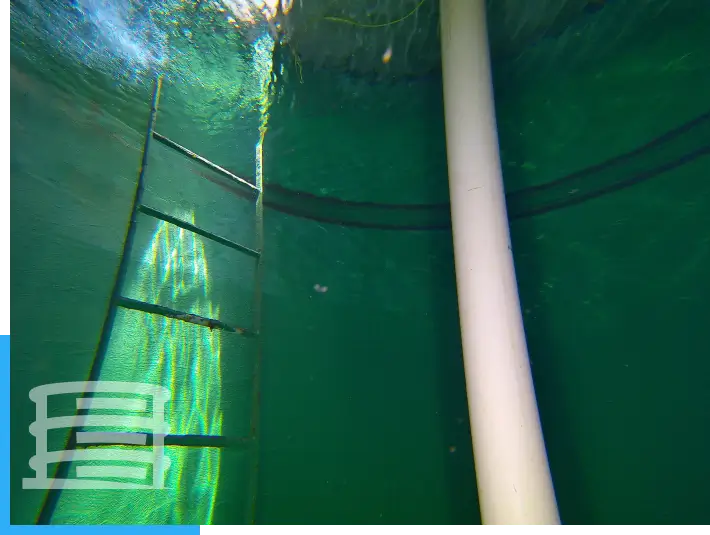

A Remotely Operated Vehicle inspection is a robotic-lead assessment of the inside of your tank, with no requirements for personnel to enter your assets.

Drone-like equipment is remotely directed throughout tank systems, conducting an inspection safely and virtually risk-free. These are normally carried out in potable water and fire water tanks.

ROV tank inspections are the most innovative tank examination and servicing solution our industry has to offer, proving the most popular method for tank service providers and clients due to its:

- Efficiency and convenience.

- Low-risk operational methods.

- Economical and low-cost processes.

- Superior data-capturing capabilities.

- Ability to not require tanks to be drained and refilled.

- Ease of generating reports from recorded data.

Manned/Dive Team Inspections

Traditionally the most practical tank inspection method, dive teams are AM Tanks’ secondary inspection service, utilized primarily under circumstances where ROV assessments can’t be performed.

This involves physically sending personnel into tank assets to manually assess the unit and its components individually. While we guarantee highly-accurate results conducting both manned and ROV inspections, AM Tanks aims to reduce human-related risks wherever possible by recommending our remote solutions.

What’s Subject to an Inspection?

While AM Tanks recommends asking local authorities for advice on region-specific regulations and standards, most of the following will require regular inspection and maintenance services:

- Field-assembled storage tanks of all sizes and capacities.

- Indoor/aboveground commercial storage tanks.

- Portable or relocatable tank systems - Pillow and bladder tanks.

- Some secondary containment or emergency containment setups.

Licensed & Accredited

AM Tanks’ goal is ultimately to provide certified assurance that your assets are safe and compliant according to your local regulations. Our team is fully licensed and trained to operate ROV inspection drones and to enter tanks where required.

We’ll provide a complete report detailing our actions, findings, results, and recommendations regarding your inspections, with follow-up maintenance services suggested.

AM Tanks is also licensed to carry out highly specialized UAV/ROV Marine & Underwater Drone Inspections!

Fitting & Component Inspections

Some regions may require flanges and fittings to be inspected as part of a regular functionality test and general inspection. AM Tanks test piping networks using advanced cameras that probe components to check for corrosion, blockages, and other damage.

We’ll follow an industry-designed inspection checklist ensuring we don’t miss a single square inch of surface or pipe structure during the examination.