Galvanized steel panel tanks are widely used for storing large volumes of water in industrial, commercial, and municipal facilities. Their strength, durability, and long service life make them a dependable choice for applications where consistent and secure water supply is essential. Whether the goal is fire protection, process water storage, or potable water distribution, galvanized steel tanks provide a balance of structural integrity and cost-efficiency.

What are Galvanized Steel Panel Tanks?

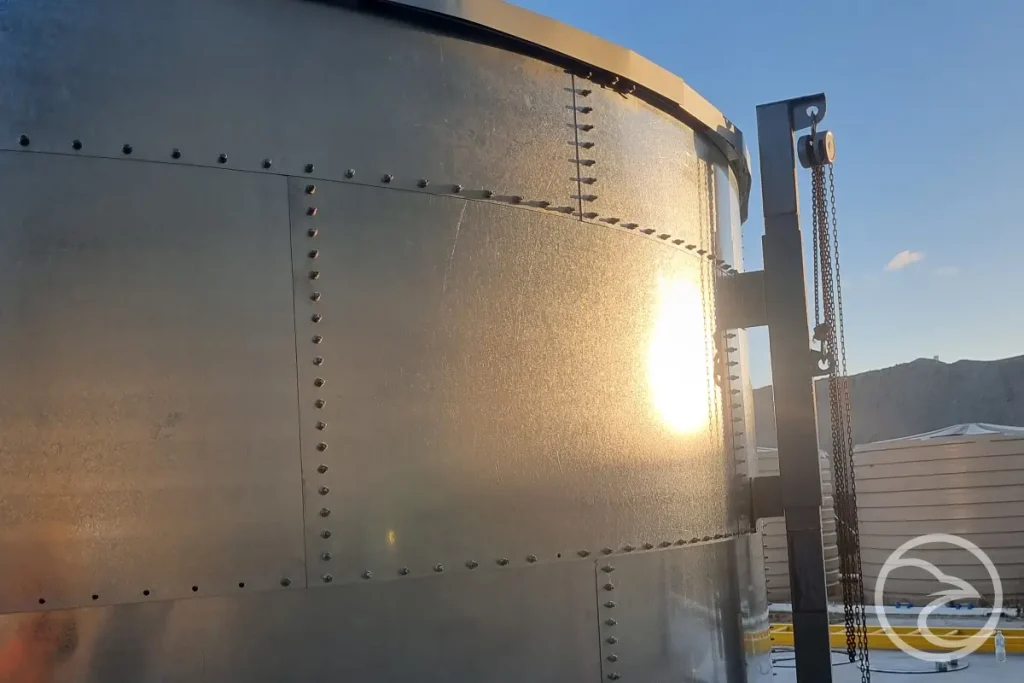

These tanks are constructed from prefabricated steel panels that are hot-dip galvanized (see HDG Panel Tanks for full specifications). The sectional panel design allows tanks to be transported in compact form and assembled directly on-site. This modular construction makes galvanized tanks suitable for a wide range of installation environments, including rooftops, remote zones, and facilities with restricted access.

Why Hot-Dip Galvanizing Matters

Hot-dip galvanizing involves coating steel components in molten zinc, creating a protective barrier that shields the metal from moisture, oxidation, and chemical exposure. This corrosion-resistant coating is key to the long-term performance of the tank, especially in outdoor or industrial conditions.

Key advantages include:

- Long-lasting protection against rust and corrosion.

- Minimal maintenance compared to painted or untreated steel.

- Reliable performance in high-moisture or coastal areas.

- Extended service life with reduced repair frequency.

Typical Applications of Galvanized Steel Panel Tanks

Galvanized panel tanks are used across many industry sectors:

- Fire Protection Water Supply: Reliable storage for sprinkler and hydrant systems.

- Industrial Process Water: For manufacturing, processing, cooling, and rinsing systems.

- Potable Water Storage: When paired with approved internal liners or coatings.

- Agricultural Water Distribution: Irrigation, livestock and seasonal storage.

- Commercial and Institutional Facilities: Hospitals, schools, and housing developments.

Their design flexibility makes them suitable for both new projects and replacement of aging concrete or welded steel reservoirs.

Structural Benefits of Panel Tank Construction

- Modular and Scalable: Capacity can be increased later by adding more panels.

- Easy to Transport and Install: Reduced need for heavy lifting equipment.

- Adaptable to Different Site Conditions: Suitable for ground-level, elevated frames, or roof installations.

- Simple Component Replacement: Individual panels can be changed without dismantling the entire tank.

Maintenance and Service Life

Galvanized steel tanks are designed for long-term stability. Routine maintenance typically includes:

- Visual inspection of steel panels and joints.

- Cleaning sediments or biofilm from the interior.

- Checking the liner (if installed) for wear.

Because the galvanization layer protects the steel from corrosion, maintenance demands are lower compared to standard steel constructions.

Final Thoughts

Galvanized steel panel tanks provide a strong and dependable solution for large-scale water storage. Their balance of structural performance, corrosion resistance, and modular flexibility allows them to meet the needs of diverse industrial and commercial applications. When properly installed and maintained, these tanks deliver decades of reliable service with minimal operational disruption.